From Empty Fruit Bunches into Biomass Pellets

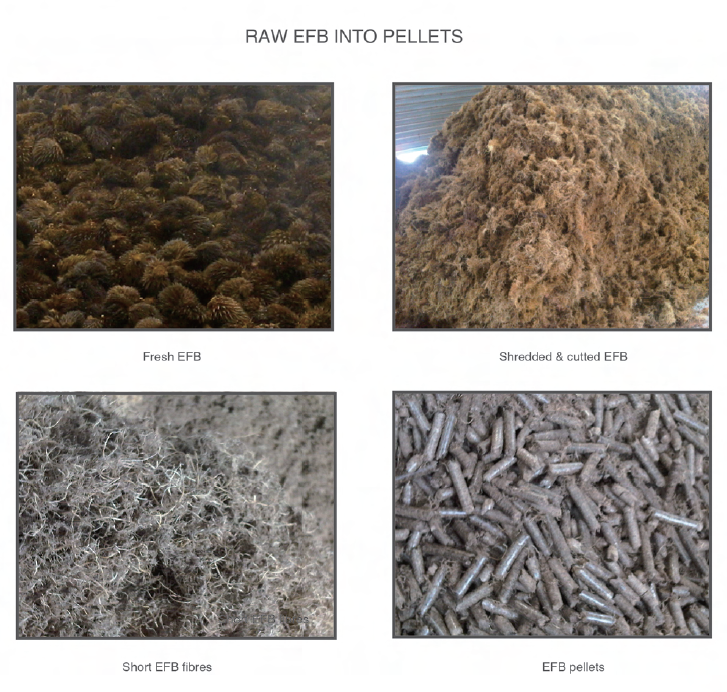

As we know, Pellets can be made of sawdust and shavings and agricultural waste such as rice husk and wheat straw. However, Empty fruit bunches(EFB) can be put into use for pelletization as well. Over the past decades, forest materials have been used in a wider range while the EFB material seems like an untapped resource for pelletization. Actually in the wake of development of renewable energy, the higher requirement for expansion of feedstock application for pelletization is also put forward. Comparing with wood material, EFB material possesses also the features of cost efficiency and sustainability, not least for industrial grade pellets destined for heat and power. Palm fiber or palm silk is a kind of biomass materials is by-product of palm after oil extraction. It is also called EFB for short. It is featured of high content of oil and water, high hardness and strong tenacity. These features make palm EFB a great material for pelletizing, but also make it more difficult to pelletize. Specialized EFB Pellet Mill is needed to produce pellets from palm fiber or palm silk.

Link to pellet mill to know how to make EFB Pellets

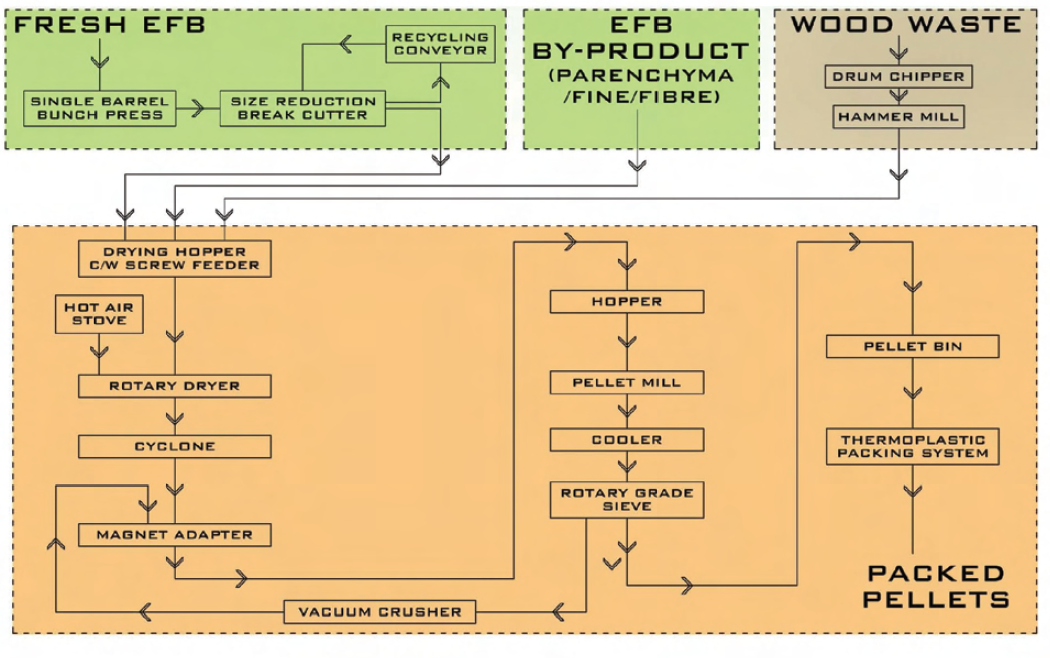

The palm oil industry of Southeast Asia boasts the largest and richest resources around the globe, representing a huge amount of unutilised raw material for pelletization. Across the whole Malaysia alone there are more than 400 crude palm oil mills. In this project, the EFB pellet plant is built beside a palm oil mill where the palm empty fruit bunches is abundant and easy to transport to cut down the prime cost. The palm EFB pellet line consists of sieving machine, drum dryer, wood hammer mill, Ring Die Bio pellet Machine, cooler and packing scale. The compressed palm EFB pellets are high in density and have a relative high consumption value because of the outstanding performance of the pellet machine and the rich fiber and cellulose content in the raw material.

There is no denying that EFBs due to the loose and voluminous with a fibrous and stringy structure are tough to be handled in some procedures of pelletization such as cutting, shredding, pelletizing and drying. Thanks to the R&D of EFB pelletization, the material can be used. For instance, an EFB pellet production line may consists of three units, pretreating section for size and moisture reduction to produce 20mm fine fibers at 20-25% MC, pelletizing unit and cooling and packaging unit. At the stage of cleaning, a lot of solid content can be separated from fibers so that the solid will consist mainly of parenchyma and fine fibers which happen to be suitable for pellet production.

--------------------------------------------------------------------------------------------------------------------------------------------------

News

- Small Pellet Machine Manufacturer-Kingman

- Application of Wood Pellets and Use of Biomass Pellets

- From Fossil Fuel into Biomass Pellet Fuel

- Biomass Pellet Making Machines Market

- Applying of pellet stoves for home use

- Highland pellets to build $130 million facility in arkansas

- How to deal with the blocked hammer mill

- How to Make Wood Pellets with Sawdust

- The government policy promotes the development of biomass fuel

- Market analysis of biomass pellet fuel

- Strategic positioning of renewable energy

- Biomass energy has pass through the pre assessment

- The key point of deep processing of biomass pellet

- Harbin is promoting the development of biomass machinery

- The development of biomass formation technology I

- The development of biomass formation technology II

- Biomass energy industry is now going full tilt in 2015

- Rapid increasing demand of sawdust pellet on the market

- Pellet fuel market in EU

- Chinese Biomass Energy Conference held in Beijing

- Future market development of straw pellet mill

- Peanut Shell Pellet Mill Makes High Quality Pellets

- The utilization of straw is only 5%, biomass energy needs our attention!

- Corn straw pellet machine relieves the tight supply of fuel energy

- Reasons for loose or not forming of biomass pellet mill