How to Make Wood Pellets or Biomass Pellet fuel

If you want to make biomass pellet fuel and wood pellets, the best manufacturer of homemade pellet mill, pellet machines and pellet mill equipment is Kingman.

If you want to make profitable biz from your wood waste material and agricultural waste, you thus need turn them into wood pellets and biomass pellet fuel. As a result, you are supposed to find the best solutions to making pellets from wasted material. You may ponder over the working principles of pellet machines or you perhaps hope to know the benefits of running a pellet mill equipment or maybe you would like to get to know how to maintain a pellet plant. You should not worry too much because Kingman can help you whole-heartedly to establish a successful pellet business. The specialized equipment for making wood pellets and biomass pellet fuel made by Kingman have been working worldwide to serve clients at home and abroad already, which also has won trust and praises from clients.Speaking of scale of a pellet plant or production of pellet, actually it seems more easier to develop a homemade pellet mill, however, you should have realized and found out that two primary needs count most, namely, the raw material and also the equipment to create biomass pellets.

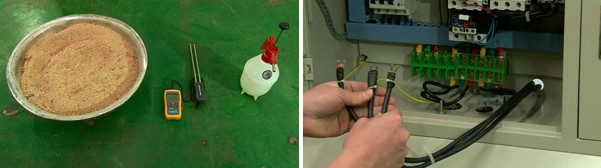

Raw Material

As a matter of fact, wood pellets or biomass pellet fuel can be made from a variety of materials which should be known by you before you throw away your wood material such as wood sawdust, saw shavings or wood chips. Some people even use the wood waste as mulch, but the value of mulch is not so positive as pellet fuel, and other people even mix wood waste with domestic garbage and pour them into garbage stations or just bury them underground. To tell the truth, both softwood and hardwood can be applied more usefully. What's more interesting remains that you can also make biomass pellets from a multitude of materials such as switch grass, grain, corn cobs, corn stalks, paper, saw dust, distiller grain, and many more. You will find as many potential materials as you can to make profits from them.

The Equipment

When we talk about making wood pellets, it doesn't just about pellet machines which is just the main equipment within a pellet plant. And there are more auxiliary equipment including hammer mills, dryers, coolers, bagging machine, and central heating boilers. If you are capable of collecting purchasing a large amount of biomass waste, you will be so lucky to start up a massive commercial manufacturing pellet line. Given the limitation of material access, you can also make pellets on a small scale, or maybe domestically with a flat die pellet machine, Technically, homemade wood pellets or biomass pellets come directly from sawdust within a small-scale pellet mill if moisture content and size of sawdust are qualified. But from time to time, you ought to put a hammer mill into use or a drying system to qualify raw material prior to pelletization.

The Procedures

With regard to the pelleting procedures, we have to design a pellet plant yet based on material species, moisture content, size, investment budget of your schedule, workshop size for the pellet plant and so on. First, the moisture content of raw material shall be kept around 13%-15%, with the size of material not more than 5mm. Actually fiber and lignin content in material are also varied. A hammer mill or drying system thereof will be put into production to pretreat material.

Make Wood Pellets

Lignin is referred to as a natural substance presenting in wood and functioning like glue. In some cases, the raw material you will use may have no lignin content which happens to be the natural binding agent of material to be made into pellets and in this regard, another binding agent shall be put into application. However, there are still many adhesives can be used such as vegetable oil, clay, starch, oil, or wax just according to the specific material traits and species you will use.

Through a pelletizer, raw material shall be extruded via a die mold and oress rollers. The press rollers pressure will squeeze loosened material into characteristic tubular shape. After they are discharged from the pelletizer, they will be hardened as solid fuel.

News

- Small Pellet Machine Manufacturer-Kingman

- Application of Wood Pellets and Use of Biomass Pellets

- From Fossil Fuel into Biomass Pellet Fuel

- Biomass Pellet Making Machines Market

- Applying of pellet stoves for home use

- Highland pellets to build $130 million facility in arkansas

- How to deal with the blocked hammer mill

- How to Make Wood Pellets with Sawdust

- The government policy promotes the development of biomass fuel

- Market analysis of biomass pellet fuel

- Strategic positioning of renewable energy

- Biomass energy has pass through the pre assessment

- The key point of deep processing of biomass pellet

- Harbin is promoting the development of biomass machinery

- The development of biomass formation technology I

- The development of biomass formation technology II

- Biomass energy industry is now going full tilt in 2015

- Rapid increasing demand of sawdust pellet on the market

- Pellet fuel market in EU

- Chinese Biomass Energy Conference held in Beijing

- Future market development of straw pellet mill

- Peanut Shell Pellet Mill Makes High Quality Pellets

- The utilization of straw is only 5%, biomass energy needs our attention!

- Corn straw pellet machine relieves the tight supply of fuel energy

- Reasons for loose or not forming of biomass pellet mill