What is biomass pellet mill?

Biomass pellet mill take sawdust, rice husk, tree barks and other biomass as material, to solidify them into biomass pellet fuel with high density after processing. This kind of pellet fuel is eco-friendly and energy saving, it is a kind of renewable resource with high efficiency and it has good economic efficiency.

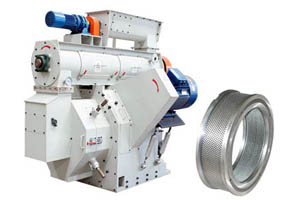

Classification of biomass pellet mill: flat die pellet mill and ring die pellet mill.

Which one is better, ring die pellet mill or flat die pellet mill?

The flat die pellet mill makes use of a die that receives the powder near the top of the device, where it is pressed firmly with a roller. As the roller progresses over the powder, it is compressed and forced through slots in the body of the die. Cutters are used to clip the compressed powder into pellets as it emerges from the slots. The flat die pellet mill often applied to small and medium sized production which requires lower hourly output and the materials with large adhesive force.

The ring die pellet mill is equipped with radial slots along the surface of the die. The powder is fed into the device and spreaders smooth the powder into a more or less even coat. Two or more rollers compress the substance, pushing the powder through the radial slots. As with the flat die pellet mill, cutters cut the pellets as they emerge from the slots. There are three main advantages of ring die pellet mill: 1.Large production, nice pellet forming shape and high density( 1-1.3%). 2. No additives are needed while pelletizing. 3. The roller and ring die are of balanced wear. The main disadvantage is the relatively high power consumption.

Ring die pellet mill has high yield, but load and unload is not very easy when maintaining as well as the high cost for repairing; flat die pellet mill has low yield, but it is easy to maintain with low cost. If it is going to produce pellet fuel with large scale, the ring die pellet mill is suggested.

What's the difference between straw pellet fuel and the straw briquette fuel?

Straw pellet fuel is a kind of eco-friendly fuel with the size of 5-8mm and round shape. It has been widely used in developed countries in European and American, and it usually used in the fire place. More and more people begin to use the pellet fuel in China. For the straw briquette fuel, it usually has big volume with the diameter 50-100mm. The density of briquette is the same with the pellet fuel. It can replace of coal fuel, and it’s an eco-friendly fuel.

Read:How to make wood pellets

At present, biomass fuel mainly used for biomass power generation and biomass gasification in China. As the emerging of biomass pellet mill, a new method of producing biomass energy—biomass densification has emerged. But this method has not been widely applied, and it is not mutual enough. Many people think that straw is a wasteful thing. In rural areas, the way of dealing with the straw is to burn them directly. It not only brings bad effect to the atmosphere, but also wastes the resources. As a matter of fact, it is a kind of precious biomass energy. Therefore, the emerging of biomass pellet mill not only protects the environment, but also contributes an effect to the biomass energy.

The volume of biomass pellet fuel which compressed by the biomass pellet mill is only about 1/30-1/40 of the volume of the material; bulk specific weight is 10 times higher than the material; the burning resistance is much higher than the material. Second, the pellet fuel is to process peanut shell, straw, sawdust and other agro wastes under the room temperature. The density of pellet after densification is 10 times of the material. Therefore, it is easy to transport and storage. Third, the technological process is from storage, destroying, drying, formation and package. It is easy to operate.

Selecting of material for biomass pellet mill

Material for biomass pellet mill is very broad, and it can be series of wooden powdery material like sawdust, wood shaving and wood flour. It also can be corn straw, rick husk, bean straw, sorghum straw and other agriculture wastes straw. Regardless of thermal efficiency or amount of material supply, sawdust pellet and straw pellet are the first choice for the biomass pellet mill. It is better to use sawdust of soft wood to make pellets. Many clients usually neglect this issue when purchasing the material for pellet mill. Actually, the sawdust of soft wood is much easier to compress. If the soft wood sawdust can not be purchased, mixing a little straw powder in the material can improve the pelletizing efficiency significantly. In general, the moisture content of material of sawdust pellet or straw pellet is about 15%-25%. If it is too high, the compressed pellet is loose, which is easy to crush or break during the package or transportation. If it too low, the pellet is difficult to compress. And the pellet has low pelletizing efficiency with much powdery material. Therefore, we suggest that use the way of sun-cure or drying to reduce the moisture content of material, or add water content to the material to increase the moisture content of feedstock.

How to deal with the dust pollution during the operation of biomass pellet mill?

It is suggested that the users use the cloth screen to cope with it: the dust pollution mainly consists of gland, backing plate, trunk piston and shell. The trunk piston and shell are equipped with air-bleed hole. The advantage of using high efficiency dust pollution in the pellet plant is to avoid the dust attaching to the cylinder wall by the vibrating force. Therefore, the aim of reducing dust is accomplished, it not only up to the policy standard, but also advantageous to improve people’s environmental consciousness. It is advantageous to environmental protection and protects workers healthy.

Kingman boasts the best pellet mill manufacturer and supplier of China. Primary productions of KMEC: series of flat die pellet mill, crushing machine, ring die pellet mill production line etc. Our products have been exported to many foreign countries. If you have question to our products, please feel free to contact us.

-----------------------------------------------------------------------------------------------------------------------------------------------------

How to start a pellet plant is usually raised by clients or potential clients who possess abundant and sufficient biomass material such as wood blocks, wood sawdust or saw shavings, bark, tree branches and twigs as well as rice husk, wheat straw, cotton stalks, maize stalks, corn cobs, bagasse, palm EFB, bamboo.

News

- Small Pellet Machine Manufacturer-Kingman

- Application of Wood Pellets and Use of Biomass Pellets

- From Fossil Fuel into Biomass Pellet Fuel

- Biomass Pellet Making Machines Market

- Applying of pellet stoves for home use

- Highland pellets to build $130 million facility in arkansas

- How to deal with the blocked hammer mill

- How to Make Wood Pellets with Sawdust

- The government policy promotes the development of biomass fuel

- Market analysis of biomass pellet fuel

- Strategic positioning of renewable energy

- Biomass energy has pass through the pre assessment

- The key point of deep processing of biomass pellet

- Harbin is promoting the development of biomass machinery

- The development of biomass formation technology I

- The development of biomass formation technology II

- Biomass energy industry is now going full tilt in 2015

- Rapid increasing demand of sawdust pellet on the market

- Pellet fuel market in EU

- Chinese Biomass Energy Conference held in Beijing

- Future market development of straw pellet mill

- Peanut Shell Pellet Mill Makes High Quality Pellets

- The utilization of straw is only 5%, biomass energy needs our attention!

- Corn straw pellet machine relieves the tight supply of fuel energy

- Reasons for loose or not forming of biomass pellet mill