Wood Pellet Mill in China

Due to the development of biomass industry in the world, china begins to pay more attention to the development of wood pellet mill. Along with the consciousness of energy saving and reduce emission, wood pellet mill have become the driving force for the development for economic growth.

Then what is wood pellet mill?

Wood pellet mill is a newly developed energy saving equipment. The finished products are smooth in surface and evenly pellets. Its hardness is closely to European standard. Pellet fuel is convenient in the process of manufacturing, packing, storing and transporting as a clean renewable energy. This kind of wood pellet mill is easy to operate and maintain with lower price. With the fast development of feeding animals industry and biomass energy saving project, this kind machine becomes very popular. Since it not only can process the feedstuffs for animals, such as feed for fish, chicken, pig etc, but the wood pellet mill also can process the waste biomass material to wood pellet. The final wood pellets can be burned as green fuel in pellet stove or boiler.

Features of wood pellet mill

1. Flat die are produced by international advanced equipment and has long lifespan.

2. The wood pellet mill is driven by heavy-duty gearbox, which can produce continuously in poor condition.

3. The key components are made of alloy steel which has strong and malleable texture.

4. The machine is widely used in pelletizing for wood, straw and rice hull and other biomass plants.

5. The important wearing parts are of high performance, long service time and low maintenance cost.

6. Simple operation and easy to use: high automation degree, less labor force. Only three people are needed in the process. It adopts the artificial feeding or automatic conveyor.

7. Materials adaptable: the machine adapt to various kinds of biomass materials. The size of straw particle can be from powder to 50mm length. And the moisture content is between 5% to 30%, Under this condition, the materials can be make pellets.

8. Roller auto regulation function: the principle of bi-directional rotation of the thrust bearing to adjust the pressure angle automatically, so that the materials are not crowded groups to block the machine, to ensure that the material pelleting with stableness.

Working Principles of Wood Pellet Mill:

We know the details of how pellet press working and how to make premium wood pellets. Compared with straw or grass pellets, produce wood pellets needs more heat and power. Heat is necessary for melting the natural lignin within the wood material, so that the material can be reshaped to pellets. However due to the increased density of wood fiber, more heat is required to be able to penetrate the wood. For many large wood pellet mill, dry steam is used to achieve the required temperature.

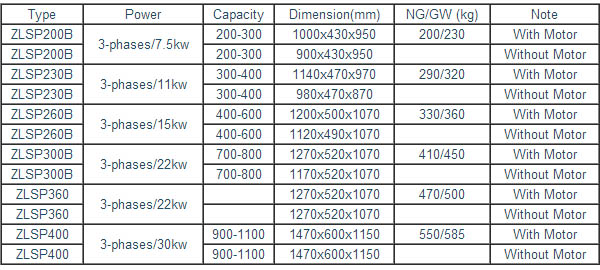

Kingman boasts the best wood pellet mill manufacturer and supplier of China. Primary productions of KMEC: series of flat die pellet mill, crushing machine, ring die pellet mill production line etc. Feed pellet mill, sawdust pellet mill of our company are popular on the market and welcome the clients to purchase our products.

News

- Issues that need to concerned during the applying of straw pellet mill

- How to make quality sawdust pellets

- Maintain of Screw Extrusion Pellet Mill

- Renewable resources get more subsides from the UK government

- Wood pellet mill is becoming pioneer of energy-saving and emission-reduction

- fuel per year(project) is being built in Chang Bai County Jilin provinces

- Shandong province has first exported biomass fuel

- Further processing of corn straw pellet

- India is developing biomass energy

- Drax secures forward power sales despite tough market

- How to use wood pellet stoves

- More pellet plant is being built

- Eco-friendly smokeless straw pellet fuel

- Factors which affect the compacting performance of biomass pellet fuel

- Biomass briquetting fuel is facing a good opportunity to make progress

- FAQ of Pellet

- Screw Type Extrusion Pellet Mill

- Compression Ratio of Pellet Mill

- Improving air quality through promotion of biomass stoves - KMEC Pellet Plant

- Effect of pore size of sieve to the production of straw pellet mill

- Wood Pellet Mill For Sale

- Wood Pellet Mill in China

- Wood Pellet Mill Machine

- The Southeast Asia pellet market is in depression

- Development prospect of fuel made by biomass pellet mill of Jilin province