Breaking News About Biofuel Development In China

China's State Council has issued the Airborne Pollution Prevention and Control Action Plan (2013-17), setting a goal for 2017 to have cut PM2.5 by at least 10 percent in major cities nationwide compared to the levels recorded in 2012, the China's state-run Xinhua News Agency reported.

As we know China's air pollution has become a severe problems haunting a number of Chinese cities and rural areas. Over the past year, PM2.5 became the hot spot all over media coverage across the whole country, with the international attention drawn as well. PM2.5 technically refers to an all airborne particular matter less than 2.5 microns in diameter, making it small enough to pass into the gas exchange regions of the lung. The smog shrouded so many regions of China. Besides, haze problem also makes people living in middle-east get on their nerves, not least Iran's capital city Teheran. Air pollution and climate change not only are wrecking havoc with people from some single region but have become a threat and challenge to the whole world.

In this regard, more and more people started to focus on biofuel application, in particular, the use of biomass pellets which is counted as a green and renewable fuel replacement. However, of the biomass pellets fuel, wood pellets and agro pellets fuel are classified as two kinds of new fuel due to the different raw material types put into production. Therefore, we hereby can briefly discuss about the differences of the two.

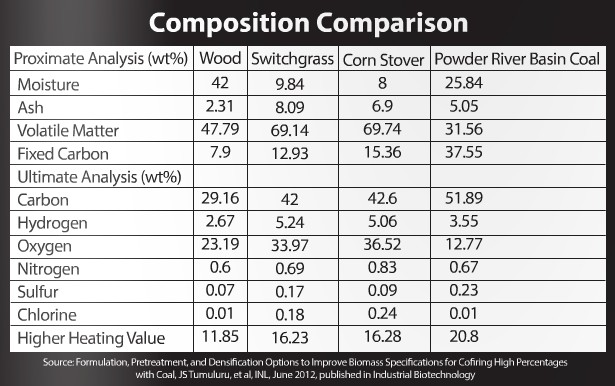

As shown in the table, Wood's lignin content at 25% or higher lends itself to supreme quality and favorable durability due to lignin's thermoplastic nature that essentially melts and binds mealy particle together into pellets. Compared with it, crop residues and perennial grasses on the other hand typically contain lignin ranging from 12% to 14%, due to which more energy to pelletize herbaceous feedstock is needed than woody biomass, said INL researchers, unless binding agent is put into use.

In light of the different characters of distinctive materials per se, technological process of pelletization may be varied. Therefore, it is widely acknowledged that binders will from time to time be applied. However, some pellet mill manufacturer or supplier to sell their products decieves and makes deceptive guarantee that their pellet mills are capable of processing a lot of biomass materials without use of binders. Eventually, your production cannot continue smoothly when you actually put the machine into production. That's why it is necessary to point it out herewith. You are also supposed to ask for detailed info about pellet mill compression ratio and what kind of raw material their pellet mill can process when you contact your pellet machine supplier. Different raw materials demand for distinguished compression ratio of pellet mill mold and the project may be altered if you are going to start a pellet plant.

Link to what is compression ratio

Link to how to start a pellet plant

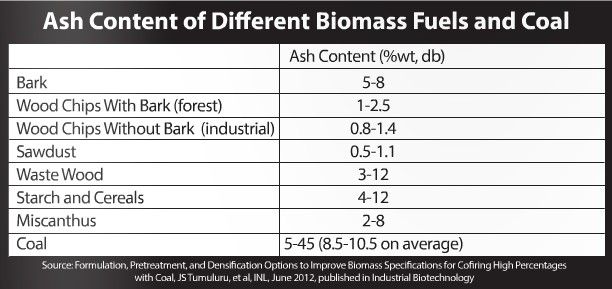

Actually, ash content also differs, along with varying levels of other elements such as clorine and silica. Because they may cause problems for power and industrial users, contributing to fouling or slagging in boilers. One possible solution to get better-quality pellets fuel from agro biomass is to blend multiple feedstocks to get a consistent content in Btu, ash content and moisture and to keep undesirable components in acceptable concentrations. Including 10-20% woody biomass in the blend can act as a binder improving durability of agro-based pellets fuel. Therefore, Finding a solution for durability and whetherability of agro pellets has been focus of some pellet machine supplier. Becuase they know the improvement in technological process enables power plants to be effective and continue to provide baseload power but still balance the requirement of environment regulations and renewable portfolios and make the transformation from conventional coal-fired power plants into CHP or biomass fuel-combusting power plants way easier.

News

- Small Pellet Machine Manufacturer-Kingman

- Application of Wood Pellets and Use of Biomass Pellets

- From Fossil Fuel into Biomass Pellet Fuel

- Biomass Pellet Making Machines Market

- Applying of pellet stoves for home use

- Highland pellets to build $130 million facility in arkansas

- How to deal with the blocked hammer mill

- How to Make Wood Pellets with Sawdust

- The government policy promotes the development of biomass fuel

- Market analysis of biomass pellet fuel

- Strategic positioning of renewable energy

- Biomass energy has pass through the pre assessment

- The key point of deep processing of biomass pellet

- Harbin is promoting the development of biomass machinery

- The development of biomass formation technology I

- The development of biomass formation technology II

- Biomass energy industry is now going full tilt in 2015

- Rapid increasing demand of sawdust pellet on the market

- Pellet fuel market in EU

- Chinese Biomass Energy Conference held in Beijing

- Future market development of straw pellet mill

- Peanut Shell Pellet Mill Makes High Quality Pellets

- The utilization of straw is only 5%, biomass energy needs our attention!

- Corn straw pellet machine relieves the tight supply of fuel energy

- Reasons for loose or not forming of biomass pellet mill