Biomass Pellet Press

Kingman, the No.1 biomass pellet press manfuacturer, is specialized in the supply of pellet presses, including wood pellet press, rice husk pellet press, straw pellet press, stalk pellet press and other pellet presses.

Pellet press is also called pellet mill or pellet machine, which is a quite important material processing facility. Pellet presses can be used to process biomass waste which includes as follows:

Agro waste: rice husks, corn cobs, peanut shells, sunflower seed shells, coconut shuck, coffee grounds, straw stalks;palm EFB, cotton stalks, sunflower seed shell, oil cake from oil and fat refining plant.

Wood waste: many spices of trees such as beech, pinewood, poplar, maple,eucalyptus, willow and any other wood material.

For a biomass pellet plant, different sizes of material can be used as well such as lumber, timber, wood blocks, shrubs, sawdust, saw shavings, twigs and branches as long as other auxiliary equipment like hammer mill and dryer are also used to pre-treat them.

We hereby put the focus on biomass pellet presses first. Just within biomass pellet machines, they can still be divided into several types such as direct motor-driven pellet press, belt-driven pellet press. Both the direct motor-driven pellet machine and belt-driven one are capable of processing biomass pellet fuel and feed for animal husbandry and aquaculture.We would like to discuss the differences between pellet press which is energized by motor directly and pellet machine which is driven by belt.

The motor-driven pellet mill main shaft is coupled with big motor, featuring swiftly accelerated speed and powerful driving force from big motor lest some loss of strength from motor to belt to main shaft. Therefore, the motor driven pellet press is more popular to process hard material.

The belt-driven pellet press can also be used to process hard material, but it is more compatible with feed manufacturing plants.The model of pellet press is commonly seen equipped with two big motors flanked in case that the driving force can be then reinforced and at the same time to keep the running of pellet press balanced.

There is a quite significant difference between feed pellet press and biomass pellet press, namely, they are subject to quite different materials and distinguished purposes. Within a feed pellet plant, material shall be vaporized for curing of material so that formed feed can be sterilized and strenghtened with thoroughly mixed nutritions. To this end material put into feed pellet press will be softened via dried high-temperature steam injection and hardness of material to some extent will be lessened, at the same time even the dried steam still contains some portion of water content which also can speed up the softening of feedstock, as a result, the pressure upon and harsh squeezing conditions for pellet press will be accordingly alleviated.Even though some energy is consumed in the process of driving force transmission from motors to belts and then to main shaft of pellet press, yet the feed pellet press performance will not be affected in light of the aforesaid.

Nonetheless, biomass pellet press taking wood or agro material will face up to much more abrasion against feedstock on the one hand, and the demands for strenghthened energy consumption will come into being. Because high temperature and super high pressure in pelleting chamber and the hardness of material will both ask for a reinforced power resource.Consequently, direct motor-driven pellet press is commonly applicable to biomass pellet plants and pellet presses.

But some clients may ponder over why some biomass pellet plants take belt-driven pellet presses too? Why are those pellet presses not energized by motors straightforward? Because there is another factor we cannot set aside, namely, production yield. Some clients push so hard on higher thoughtput from biomass pellet presses or biomass pellet plants while others may simply ask for a relatively low product output. In this respect, we will render some suggestions to cater to different demands. For instance, we may propose a large biomass pellets production yield be matched with belt-driven biomass pellet press while for a smaller biomass pellets production line direct-motor driven pellet press be put into use for the purpose of saving power input and maximizing profits for clients. Besides, we also ensure a stable pellet press performance and a mooth pellet line can be achieved.

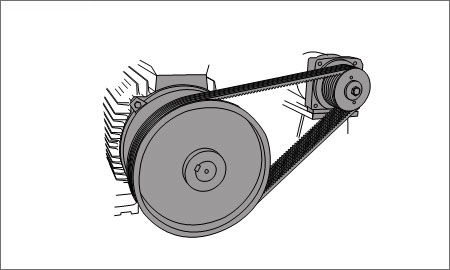

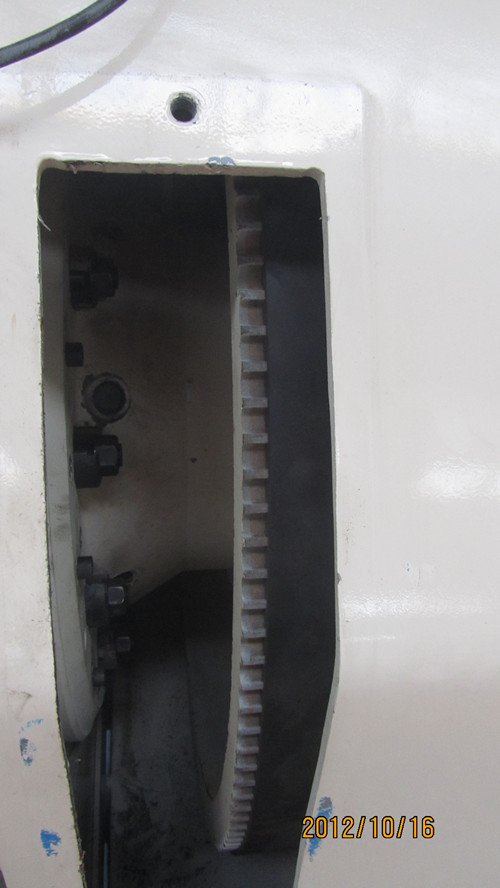

Aside from all the abovementioned situations, there are two types of belt-driven pellet presses which are worthy of being distinguished. One model is V-belt-driven pellet press and the other goes to corrugated belt-driven pellet mill. The V-belt ones possess a function of safeguarding mainshaft via skipping of V-belt lest some clogging happens to pellet press. And the corrugated belt-driven pellet machine is mounted with jagged big belt to reduce power consumption during the process of energy transmission from big motor to the main shaft of pellet press.The jagged belt seem like growing with big teeth which will occlude with jagged surface of the main shaft wheel so that belt will not skip. For emergent shutdown, shear pin will play a big role.

Kingman has accumulated more experience in offering the most appropriate design for clients who will then rest assure a professionally manufactured pellet press and pellet plant can be made.

News

- Small Pellet Machine Manufacturer-Kingman

- Application of Wood Pellets and Use of Biomass Pellets

- From Fossil Fuel into Biomass Pellet Fuel

- Biomass Pellet Making Machines Market

- Applying of pellet stoves for home use

- Highland pellets to build $130 million facility in arkansas

- How to deal with the blocked hammer mill

- How to Make Wood Pellets with Sawdust

- The government policy promotes the development of biomass fuel

- Market analysis of biomass pellet fuel

- Strategic positioning of renewable energy

- Biomass energy has pass through the pre assessment

- The key point of deep processing of biomass pellet

- Harbin is promoting the development of biomass machinery

- The development of biomass formation technology I

- The development of biomass formation technology II

- Biomass energy industry is now going full tilt in 2015

- Rapid increasing demand of sawdust pellet on the market

- Pellet fuel market in EU

- Chinese Biomass Energy Conference held in Beijing

- Future market development of straw pellet mill

- Peanut Shell Pellet Mill Makes High Quality Pellets

- The utilization of straw is only 5%, biomass energy needs our attention!

- Corn straw pellet machine relieves the tight supply of fuel energy

- Reasons for loose or not forming of biomass pellet mill