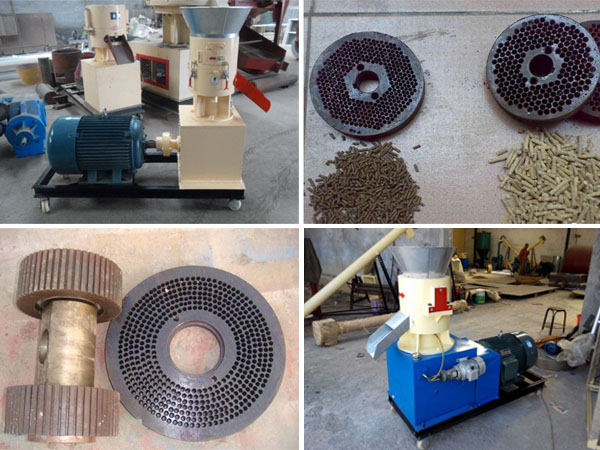

How to repair the roller in flat die pellet machine

It would affect the normal production when the roller in the flat die pellet machine wears. Then, how can we repair the roller of the flat die pellet machine apart from the daily maintenance? Generally, there are two kinds of situations, one is severe wear that the roller must be replaced; the other is slight wear and can be repaired.

1. Severe wear

When the roller of flat die pellet machine is badly worn and can no longer be used, it has to be replaced.

2. Slight wear

(1) Check the tightness of the roller, and the roller would wear out when it is too tight. Then, the operator need to loose the roller appropriately.

(2) Check the swing of the main shaft, which must be balanced. It can be effectively solved by adjusting the clearance of the bearing.

(3) Check whether the ring die and roller are matched, and if not, adjust immediately.

(4) Check the material distribution knife of the equipment. The distribution of material would be not uniform If the material distribution knife is broken. It can also lead to the wear of the roller. The material distribution knife can be adjusted or replaced.

(5) Check the feeding knife, adjust the angle and tightness of feeding knife. There should be no sound of friction in the process of making pellets.

(6) Check the raw materials. The materials should not contain any hard objects such as stone or iron, which will not only wear down the roller but also damage the cutting knife. (Get to know how to make wood pellets)

Above is the experience that our company summed over the years, hope to be helpful to biomass pellet machine operators. If there are any other problems in the production process, please contact us at any time.

--------------------------------------------------------------------------------------------------------------------------------------------------------

News

- How to make biomass pellets?

- What are the reasons for different length of biomass pellets?

- Easily blocked parts of biomass pellet machine should be cleaned regularly

- How to improve the die life of wood pellet mill?

- How to adjust the pellet length of wood pellet mill?

- Four tips for making high quality pellets with biomass pellet machine

- The factors affecting the production speed of biomass pellet machine

- The use and precautions of the ring die in wood pellet mill

- The structure and working principle of ring die pellet machine

- What's the reason for abnormal noise or sudden stop of biomass pellet machine?

- The production process of biomass pellet plant

- Pellet machine makes the pollution become resource

- What is biomass pellet fuel?

- How to distinguish the quality of accessories in pellet machine?

- The advantages and application of pellet machine

- Make biomass energy with pellet machine

- Ring die adjustment of sawdust pellet making machine

- The performance difference between flat die pellet machine and ring die pellet machine

- Does the weather change affect biomass pellet machine?

- An effective solution to output reduction of pellet machine

- Advantages of pellet machine

- Solutions to the appearance abnormality of pellet produced by pellet machine

- Five advantages of pellet machine

- How to make the service life of die in pellet mill longer?

- Matters needing attention in the application of pellet mill