Safe operation of wood pellet machine

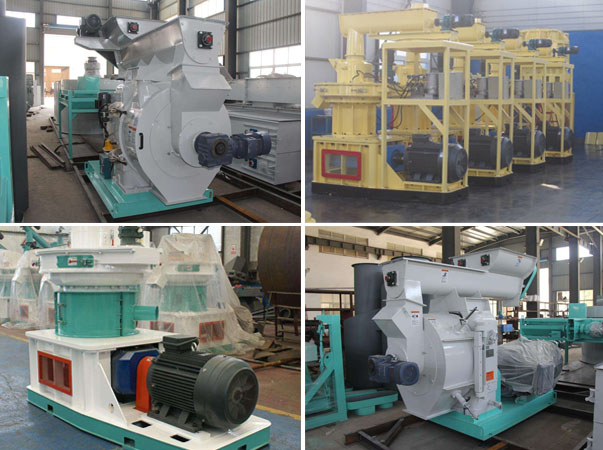

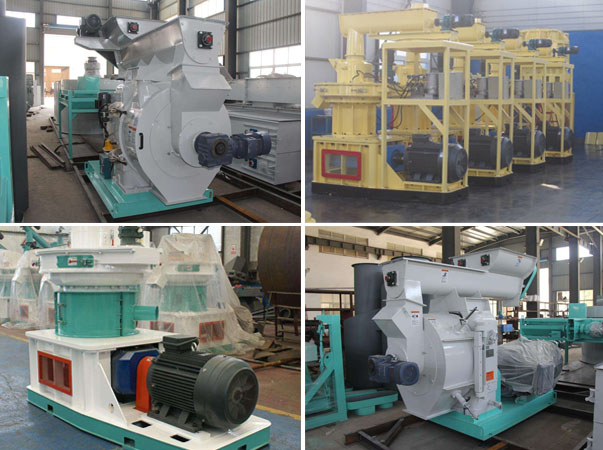

Wood pellet machine is the main product of our company. It can be used for making wood pellets with different raw materials. The following need to be noticed when using the wood pellet machine:

1. Check the grounding wire before power on. It is strictly prohibited to connect the power supply and start the machine without grounding.

2. When the power is on, do not touch any electrical components in the electric cabinet and operation desk, otherwise electric shock will occur.

3. Do not operate any switch knob with wet hands to prevent electric shock.

4. Do not check the line or replace the electrical components when the machine is live, or you will get an electric shock or injured.

5. The equipment can be repaired only by qualified maintenance personnel with corresponding operation qualifications and in strict accordance with the technical requirements of electrical maintenance so as to prevent accidents.

6. Mechanical maintenance personnel shall ensure that the machine is in the state of stop working when repairing the machine, and cut off all power supply and put up warning signs to prevent human accidents caused by sudden operation of the machine.

7. Never touch the rotating part of the wood pellet machine with your hands or other objects at any time. Touching the rotating part will cause direct damage to people or machinery.

8. Good ventilation and lighting should be provided in the workshop, and raw materials and products should not be stored in the workshop. Keep the safe operation passage unimpeded, timely clean the dust accumulation in the workshop, and no smoking or other fire use in the workshop so as to prevent dust explosion.

9. Check whether fire control and fire prevention facilities are complete and effective before work.

10. Children are not allowed to access the machine at any time, which may cause disability to children.

11. The roller bearing shall be injected with special lubricating grease every 12 hours of operation.

12. When rotating the roller by hand, the power must be cut off. It is strictly prohibited to touch the roller and die by hand or other objects during operation.

13. People who do not know enough about the mechanical performance can never operate and maintain the machine, whether it is on or off.

14. The clearance between the roller and the die shall not be less than 0.1mm, otherwise the roller and the die shall be in direct contact, which may cause excessive wear of the roller and the die and even damage the machine.

15. When the temperature of the wood pellet machine is below 10℃, the lubricating oil of wood pellet machine is easy to freeze. Make the pellet machine heat up to 10℃ or so before starting, then idle the machine for twenty minutes before granulating, otherwise the bearing of wood pellet machine would be damaged easily.

-------------------------------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------------------------------------------

In the process of receiving customer inquiries, we found that many customers asked how to regulate the moisture content when making sawdust pellets and how much water you need to add when making biomass pellets...

News

- Easily blocked parts of biomass pellet machine should be cleaned regularly

- How to improve the die life of wood pellet mill?

- How to adjust the pellet length of wood pellet mill?

- Four tips for making high quality pellets with biomass pellet machine

- The factors affecting the production speed of biomass pellet machine

- The use and precautions of the ring die in wood pellet mill

- The structure and working principle of ring die pellet machine

- What's the reason for abnormal noise or sudden stop of biomass pellet machine?

- The production process of biomass pellet plant

- Pellet machine makes the pollution become resource

- What is biomass pellet fuel?

- How to distinguish the quality of accessories in pellet machine?

- The advantages and application of pellet machine

- Make biomass energy with pellet machine

- Ring die adjustment of sawdust pellet making machine

- The performance difference between flat die pellet machine and ring die pellet machine

- Does the weather change affect biomass pellet machine?

- An effective solution to output reduction of pellet machine

- Advantages of pellet machine

- Solutions to the appearance abnormality of pellet produced by pellet machine

- Five advantages of pellet machine

- How to make the service life of die in pellet mill longer?

- Matters needing attention in the application of pellet mill

- Safe operation of wood pellet machine

- Characteristics of biomass pellet machine